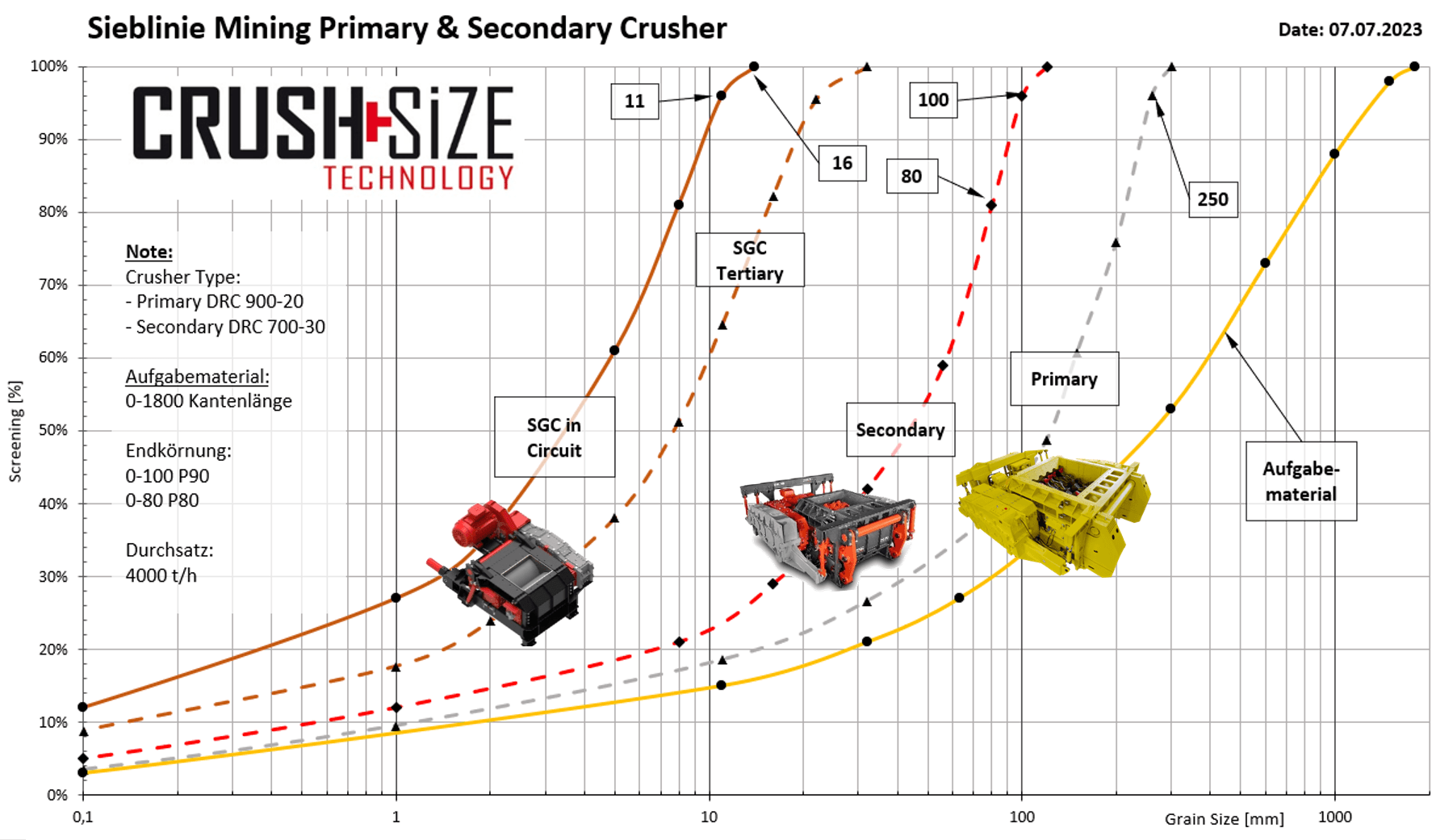

High Performance Mining describes an application in which the processing of the material takes place through crushers that allow a throughput of several thousand tons per hour. Hard to very hard materials are crushed in an energy-intensive process under high loads.

The more fine grains are produced in a process step, the more energy has to be used. With a roller crusher from Crush + Size Technology, the crushing takes place very gently, with slowly rotating rollers in order to achieve the target grain size with a small proportion of fines. As a result, the energy requirement is significantly lower than with conventional crusher technologies and wear and tear is low.