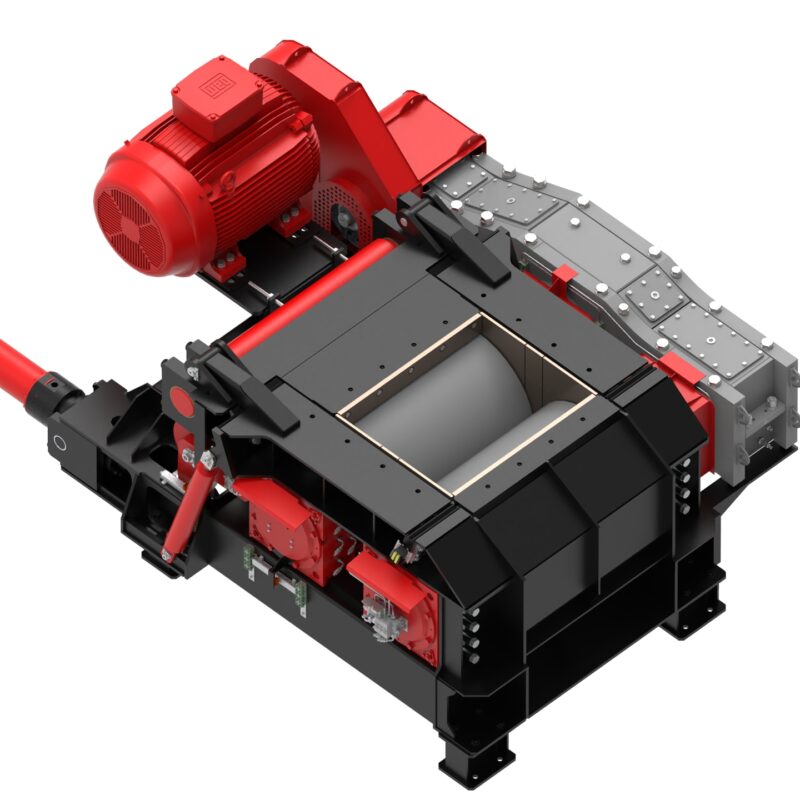

The SGC series has been specially developed to produce sand and gravel with a double-roll crusher. The crushing technology allows for the economical production of small grain sizes with minimal fine fractions. Through innovative solutions in the field of machine and control technology, it is possible to flexibly adapt the grading curve to specific requirements.

Innovative Roller Technology

New Solutions for Small Grains

A particular challenge is the efficient production of smaller grain sizes under 16 mm. Besides the sharply increasing energy consumption, the proportion of unwanted fractions in the grain size range of 0 – 2 mm also increases. In particular, the fine fraction of 0 – 0.063 mm should be avoided. Typically, crushing machines such as cone crushers, impact crushers, and vertical shaft impactors (VSI) are used to produce these grain sizes.

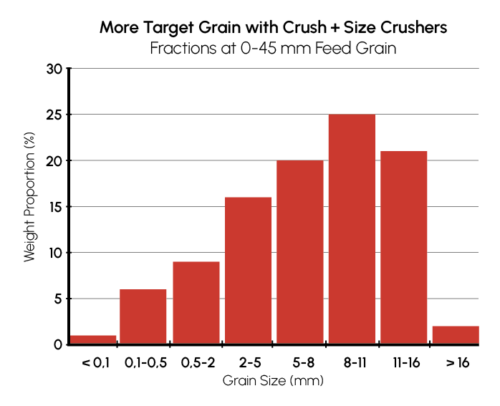

Crush + Size Technology has its core competence in the field of roller crushing technology and has developed an efficient crushing technology over the years that can efficiently produce grain sizes smaller than 16 mm with two rollers. The SGC series impresses with the smallest fine and sand fractions, thereby significantly increasing the proportion of valuable grains. The roller crusher can also efficiently produce fractions of high demand in the range of 4–11 mm.

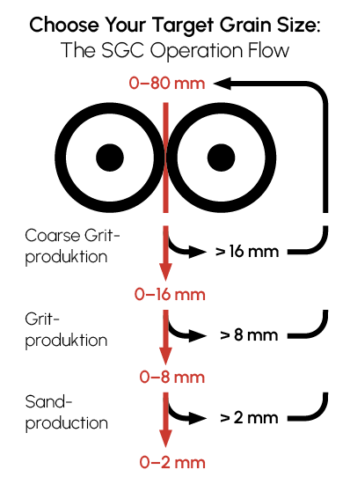

Desired Grain Size

Even in a circular process, the input grain size is efficiently crushed to the target grain size without significantly increasing the fine fraction. In this way, oversized grain fractions can be efficiently processed, and the fractions with the highest demand can be specifically produced.

The SGC series impresses with low energy consumption per ton produced and offers high throughput relative to the deployment weight. A highly effective production of the target particle size is realized.

OVERVIEW OF THE BENEFITS

TALK TO OUR EXPERTS

(other sizes available on request)

| Model | Roller Ø [mm] |

Roll Length [mm] |

Min. Weight [t] |

F100 [mm] |

P90 [mm] |

Max. Throughput [t/h] |

Min. Motor Power [kW] |

| SGC 650 | 650 | 700 | 9 | 80 | 0 – 8 | 100 | 1 x 90 |

| SGC 800 | 800 | 1000 | 15 | 100 | 0 – 8 | 200 | 1 x 160 |

| SGC 1000 | 1000 | 1200 | 22 | 120 | 0 – 8 | 300 | 1 x 300 |