Splitt ist einer der wichtigsten Zuschlagstoffe in der Bauindustrie, und gleichzeitig einer der am schwierigsten herzustellenden. Die kubische Form der Endkörnung, ein sehr enges Kornband der Zielfraktion, statische Anforderungen und geringe Feinanteile sind nur einige der Herausforderungen.

GRIT PRODUCTION

Grit from primary and secondary raw materials.

More Coarse Grain

HIGH ECONOMIC EFFICIENCY

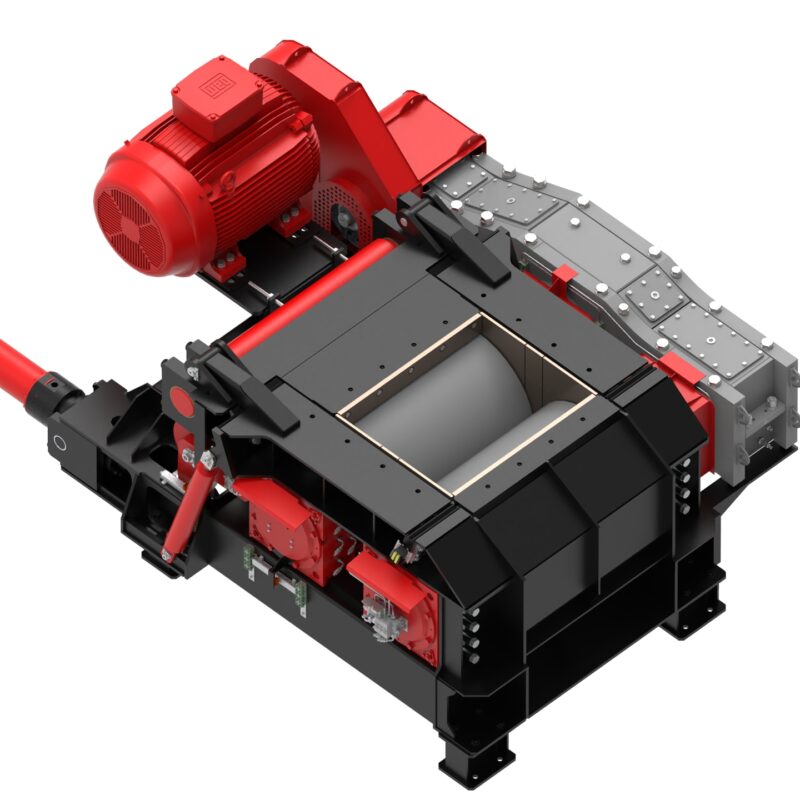

From the conviction that the gentle crushing behavior of a roll crusher can deliver perfect results for this purpose, the SGC (Sand and Grit Crusher) was born.

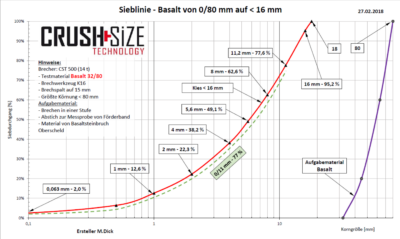

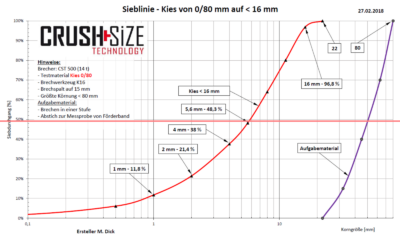

Conventional methods for gravel production crush the feed material through impact under high energy consumption and thereby produce unwanted sand and fine particles, greatly affecting the cost-effectiveness of these processes.

On the other hand, the roll crusher from Crush + Size Technology crushes the feed material in a gentle manner.

OVERVIEW OF CRITERIA IN DESCENDING PRIORITY

Between the slowly rotating rolls of the double roll crusher, feed grains from natural rock or recycled material are gently broken into high-quality gravel with a cubic grain shape.

What distinguishes this technology from conventional crushers such as cone crushers, impact crushers, and rotor centrifugal crushers (VSI) is the low proportion of undesired fines fraction (<0.063mm) and sand (<2mm). Consequently, this increases the proportion of valuable and desired gravel fractions (2-5/5-8/8-11/11-16mm). As a result, there is a significantly improved economic efficiency and simultaneously a reduced rate of disposal of undesired fractions, which makes a valuable contribution to the conservation of natural resources. At the same time, due to this efficient crushing technology, energy consumption can be reduced by up to 70% for the same crushing ratio.

SPLITTKÖRNUNG 5,6 -8,0 MM

SPLITTKÖRNUNG 4,0 -5,6 MM

SPLITTKÖRNUNG 2,0 -4,0 MM

THE CRUSHER FOR SAND AND GRIT

the SGC-Series

The SGC technology is a crusher specifically designed for the production of smaller fractions. The SGC is suitable for processing both primary raw materials such as gravel and gravel, as well as secondary raw materials such as concrete and construction waste.

(other sizes available on request)

| Modell | Roller Ø [mm] | Roll Length [mm] | Min. Weight [t] | F100 [mm] | P90 [mm] | Max. Throughput [t/h] | Min. Motor Power [kW] |

| SGC 500 | 500 | 700 | 8 | 45 | 0 – 8 | 60 | 1 x 75 |

| SGC 650 | 650 | 800 / 1100 | 10 / 12 | 80 | 0 – 8 | 100-200 | 1 x 90 |

| SGC 800 | 800 | 1.200 | 18 | 100 | 0 – 8 | 350 | 1 x 160 |

| SGC 1.000 | 1.000 | 1.400 | 24 | 120 | 0 – 8 | 500 | 1 x 300 |

TALK TO OUR EXPERTS