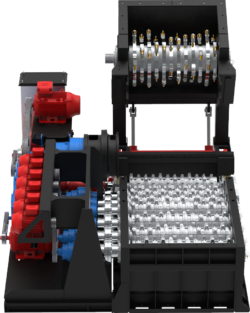

With the development of the asphalt crusher, Crush + Size Technology has set itself the challenge of combining the very complex handling handling of milled material, demolition asphalt and asphalt clods with the gentle crushing in a crusher. The aim is to road demolition in its most varied appearances of slab or the road rubble in its various forms of slabs, clods or milled material continuously and with high quality in order to be able to produce a coarse-grained end product that is product that is smaller than 80 mm.