Compact, powerful and safe

THE TECHNOLOGY OF THE SZR SERIES

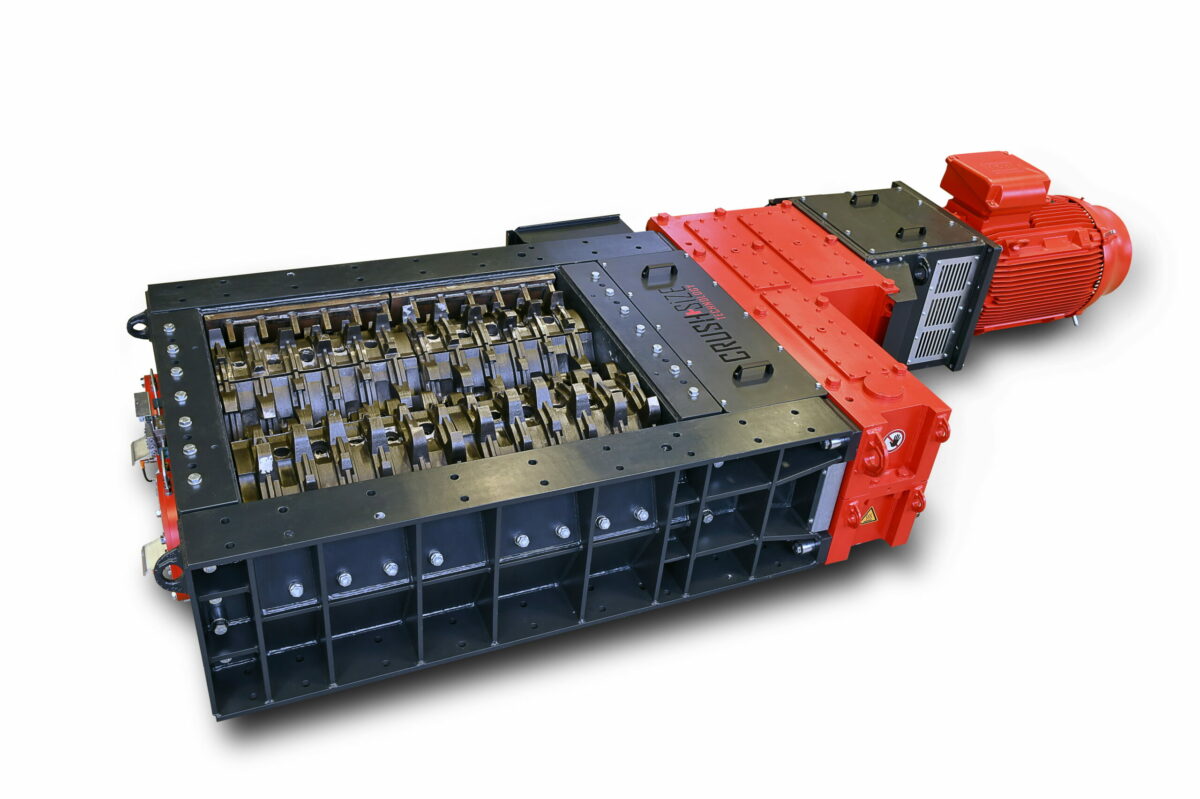

The newly developed SZR series is characterized by its compact design and high productivity. High throughputs can be achieved in a limited space.

The crusher uses the advantages of a patented crushing tool geometry to produce a high quality grain with a high crushing ratio. Another advantage is the mechanically synchronized drive design, which improves intake and grain formation.

DIVERSE USE

The compact design of the SZR series allows the crusher to be installed even in confined spaces and, at the same time, a high output can be achieved.

The crushing ratio can be assumed to be up to 1:5, depending on the properties of the feed material.

In addition to crushing mineral rocks, the Sizer can also be used in recycling. A torque-limiting overload system protects the drive against damage.

OVERVIEW OF THE BENEFITS

SIZER REDEFINED

At a glance

TECHNICAL CHARACTERISTICS

| Crushing gap | fixed | A defined grain size range is achieved through the choice of the crushing tools |

| Overload protection | integrated | By torque limiter |

| Reverse operation | automated | Blockages are resolved by intelligent automation system |

| Crushing tools | Quick-Change-System | – Replacement of individual crushing segments – Replacement of the complete roller |

| Optional Control | Machine is fully automated | – The machine and process can be monitored and adjusted via an operator panel – Feed and discharge systems can be integrated into the control |

TALK TO OUR EXPERTS