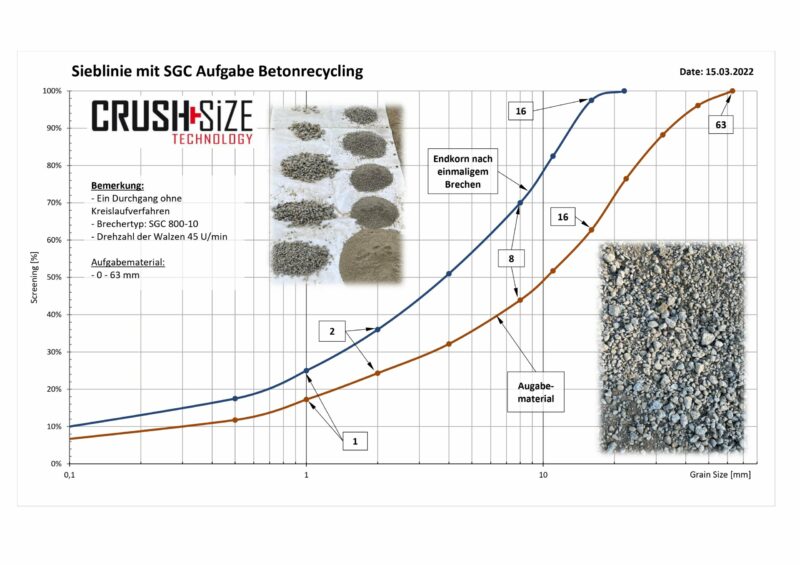

In times of increasingly scarce resources, it becomes increasingly important to reuse available construction waste with maximum quality to obtain high-quality RCL material at the end of the process chain. RC concrete, which in the past was often used solely for backfilling or for applications with low quality requirements, is increasingly expected to replace natural aggregates in concrete. This not only conserves natural resources but also places high demands on recycling processes.

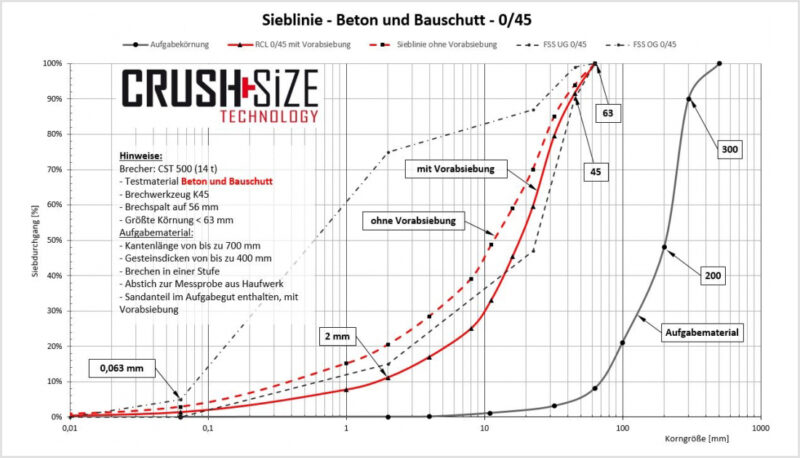

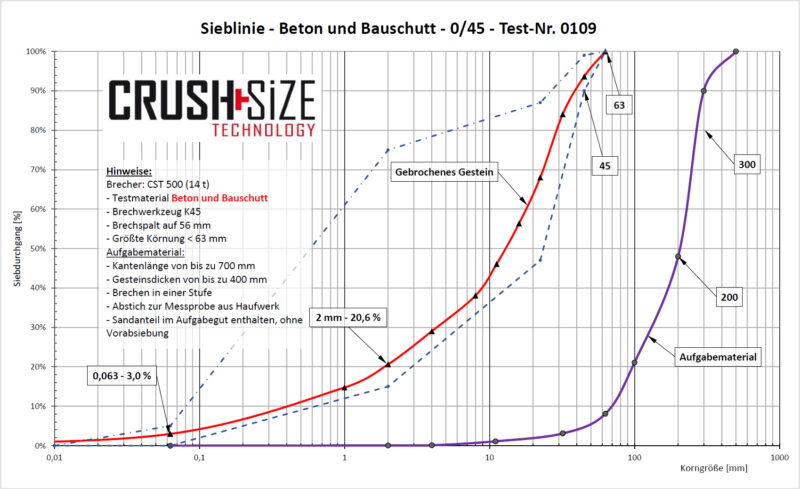

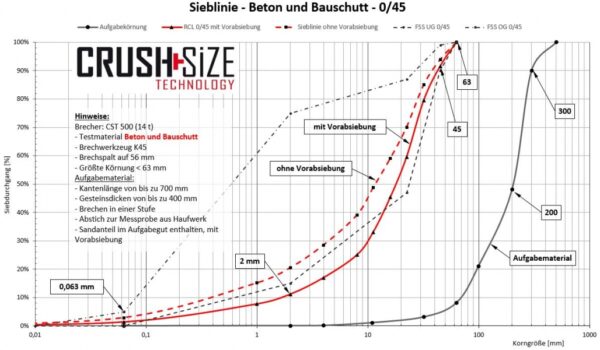

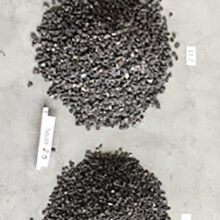

When crushing construction waste, high fines and high proportions of crusher sands are usually generated, which can prevent the incorporation of this recycled material and impair its economic viability. Waste material must be disposed of, surplus fractions are sold at discounted prices, or stockpiled.

To make concrete and construction waste recycling as resource-efficient and economical as possible, gentle crushing is necessary to prevent the production of fines and excess crusher sands.