| Crushing gap | adjustable | Adjustment during production interruption |

| Overload protection | >integrated | The loose roller dodges fast and returns automatically into the pre-set gap with |

| Reversing operation | optionally automated | Blockages are resolved independenetly |

| Crushing tools | Quick-Change-System | Fast replacement of individual crushing segments |

| Control system | Machine is fully automated |

– The machine and process can be monitored and adjusted via an operator panel – Feed and discharge systems can be integrated into the control |

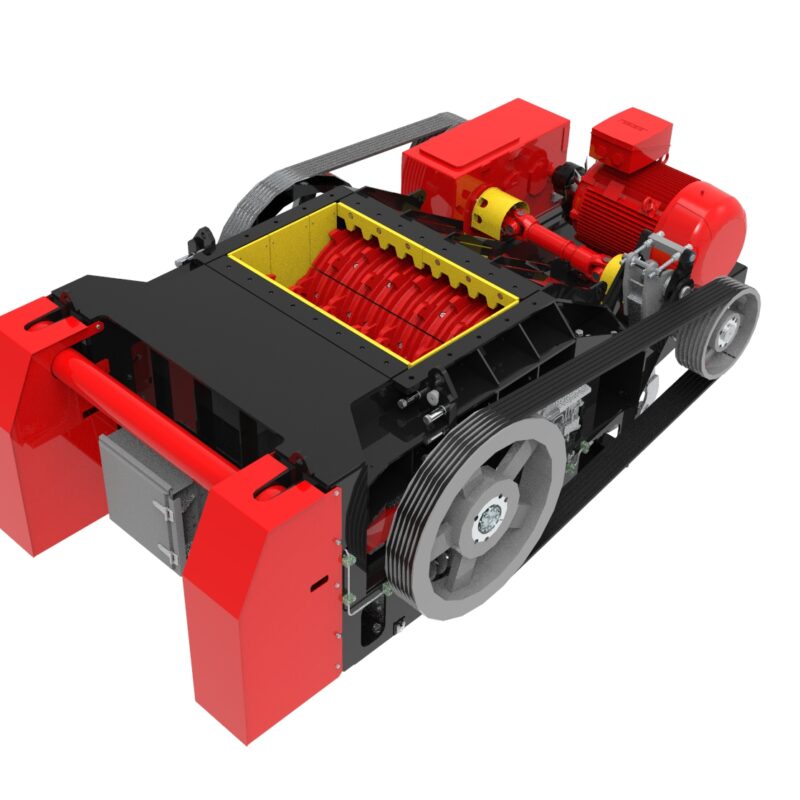

The technology of the CRC series

The CRC series features a belt drive that drives the rollers. Due to the compact design, the crusher can achieve high throughputs in a small space.

An integrated evasion mechanism provides overload protection, which enables a roller to evade foreign bodies and then move back to the starting position.

Use in soft rock

For minerals with compressive strength in the area of soft rock, this crusher is suitable for almost every application. A high quality end product is produced between the crushing rolls.

OVERVIEW OF THE BENEFITS

At a glance

TECHNICAL CHARACTERISTICS

TALK TO OUR EXPERTS

SELECTION OF CRC-CRUSHER SIZES

(other sizes available on request)

| Model | Roller Ø [mm] |

Roll Lenght [mm] |

Min. Weight [t] |

F100 [mm] |

P90 [mm] |

Max. Throughput [t/h] |

Min. Motor Power [kW] |

| CRC 600 | 700 | 1200 – 1800 | 12 – 15 | 300 | 22 – 100 | 400 | 1 x 75 |

| CRC 800 | 900 | 1200 – 1800 | 14 – 19 | 500 | 22 – 100 | 600 | 1 x 110 |