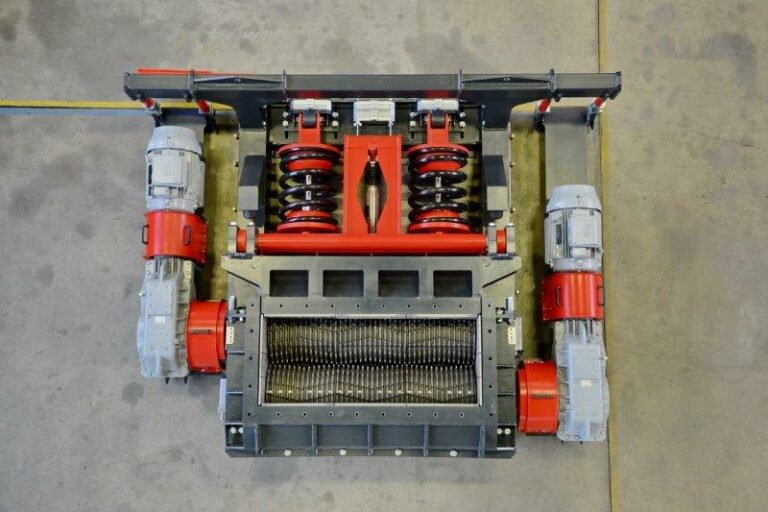

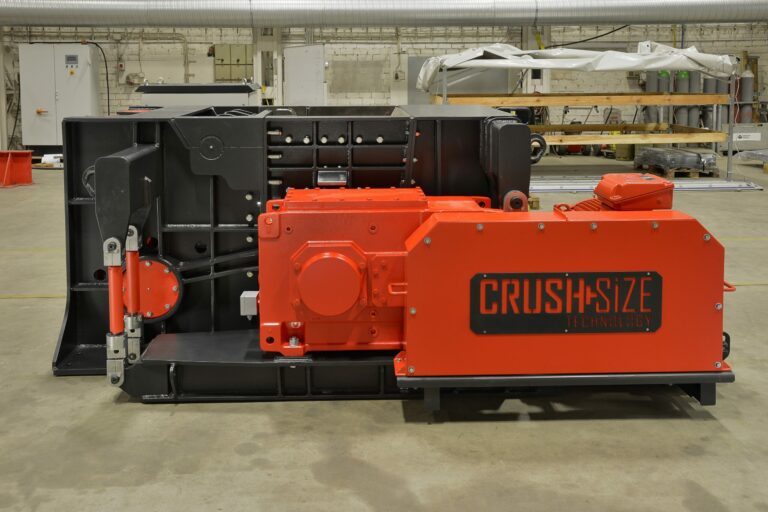

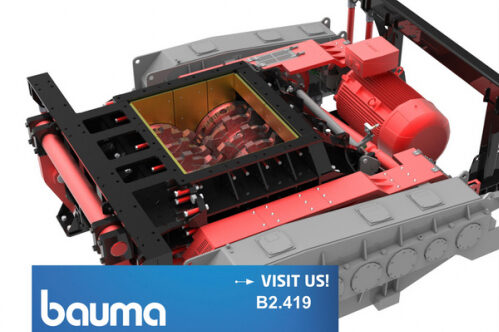

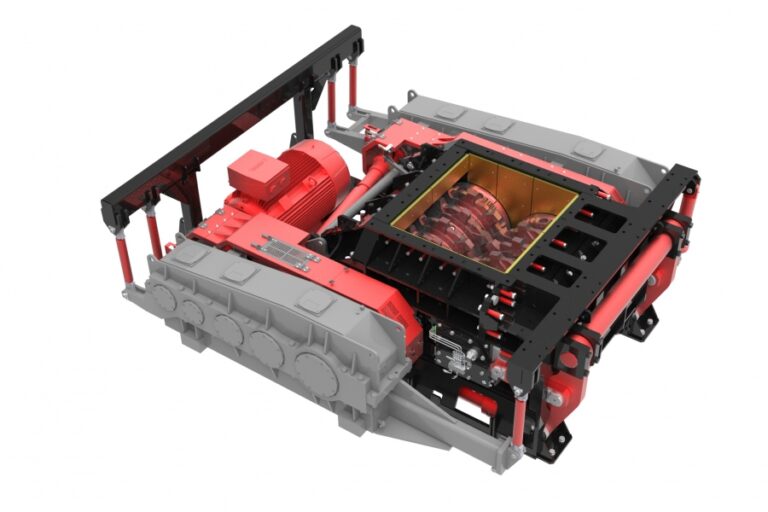

Crush + Size Technology fertigt Zweiwalzenbrecher auf Basis mehrerer technischer Innovationen. Im Fokus liegen insbesondere die Erforschung und Weiterentwicklung von Brechwalzen- und Brechwerkzeug-Geometrien, um Zerkleinerungsprozesse deutlich effektiver und effizienter durchzuführen als mit herkömmlicher oder auf dem Markt bisher bekannter Walzenbrecher-Technologie.

WILLKOMMEN BEI CRUSH + SIZE TECHNOLOGY

Zweiwalzenbrecher und Walzenbrecher für wirtschaftliche Aufbereitung.

Eine hohe Produktivität und ökonomische Arbeitsweise des Walzenbrechers verbunden mit gesteigerter Qualität des Endprodukts sind das Ergebnis einer konsequenten Weiterentwicklung.

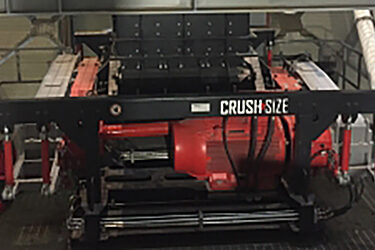

Der robuste und energieeffiziente Direktantrieb sorgt für genügend Kraftreserven in jedem Anwendungsfall.

Die Zerkleinerungs- und Antriebstechnik des Crush + Size Technology Zweiwalzenbrechers sichert Brechergebnisse, die weit über den bisher bekannten Grenzen eines Walzenbrechers liegen.

KUNDENNUTZEN IM FOKUS

Der technologische Vorteil der Walzenbrecher hilft den Betreibern, bisherige Aufbereitungsprozesse stationärer und mobiler

Anwendungsbereiche effizienter zu gestalten und ein höheres nutzbares Ergebnis zu erzielen.

Anwendungsbereiche effizienter zu gestalten und ein höheres nutzbares Ergebnis zu erzielen.

Handelt es sich um das Recycling von Bauschuttabfällen oder um die Verarbeitung von Gesteinen jeglicher Art – die gravierenden, revolutionierenden Vorteile der neuen Zerkleinerungstechnik werden auf den Anwendungsfall individuell abgestimmt und gewinnbringend implementiert.

ALLE VORTEILE

Hohe Produktivität im Zerkleinerungsprozess

Qualitativ hochwertiges Endprodukt durch innovatives Brechwerkzeug

Kosteneffizienz durch hohe Verfügbarkeit

Flexibel auf Ihren Prozess abgestimmtes Brecherkonzept

Komfortable Bedienung und sicherer Betrieb

Umweltschonende Zerkleinerung

Qualität „Made in Germany“

Nachhaltiger Nutzen für unsere Kunden